The Additive Manufacturing Innovation Centre (AMIC) supports industry in meeting the challenges of product design and development, technology adoption, manpower training, applied R&D, etc. in Additive Manufacturing.

Our team of experienced and competent professional Senior Lecturers, Senior Development Engineers and Development Technologists in various technological areas are well-prepared and dedicated to take on the challenge and needs of industry.

Our Services

- Training programmes in Additive Manufacturing/ 3D Printing

- Consultation

- Product Design & Development

- Design for Additive Manufacturing

- Rapid Tooling, Hybrid Tooling & Conformal Cooling Technology

- Rapid Fixturing

- Post Processing and Finishing

- Full Turnkey Solutions

Our Capabilities

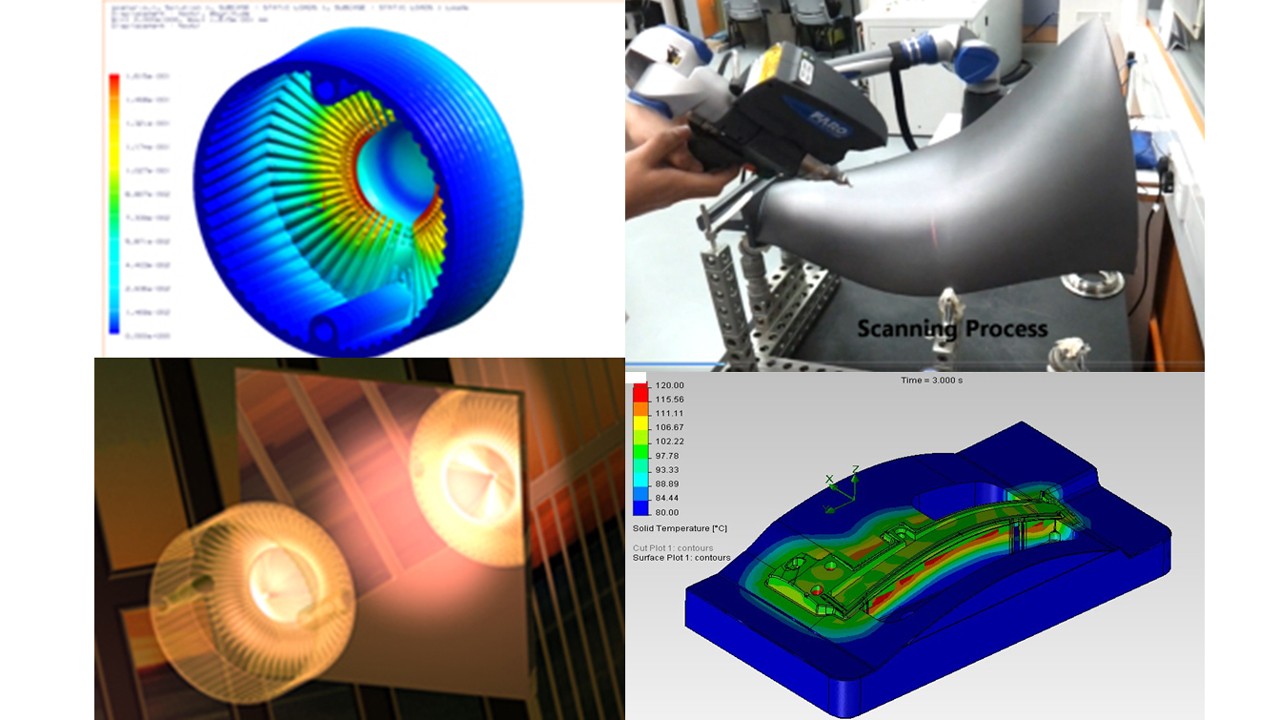

Innovative Product Design, Development and Industrial Design

3D Printing/Additive Manufacturing brings virtual designs to real life and changing our consumer market. It allows to customise the product design based on user preference. We have accumulated extensive experience working with industrial partners in consumer and medical product design, simulation, analysis and development. We are able to provide turnkey product development solutions.

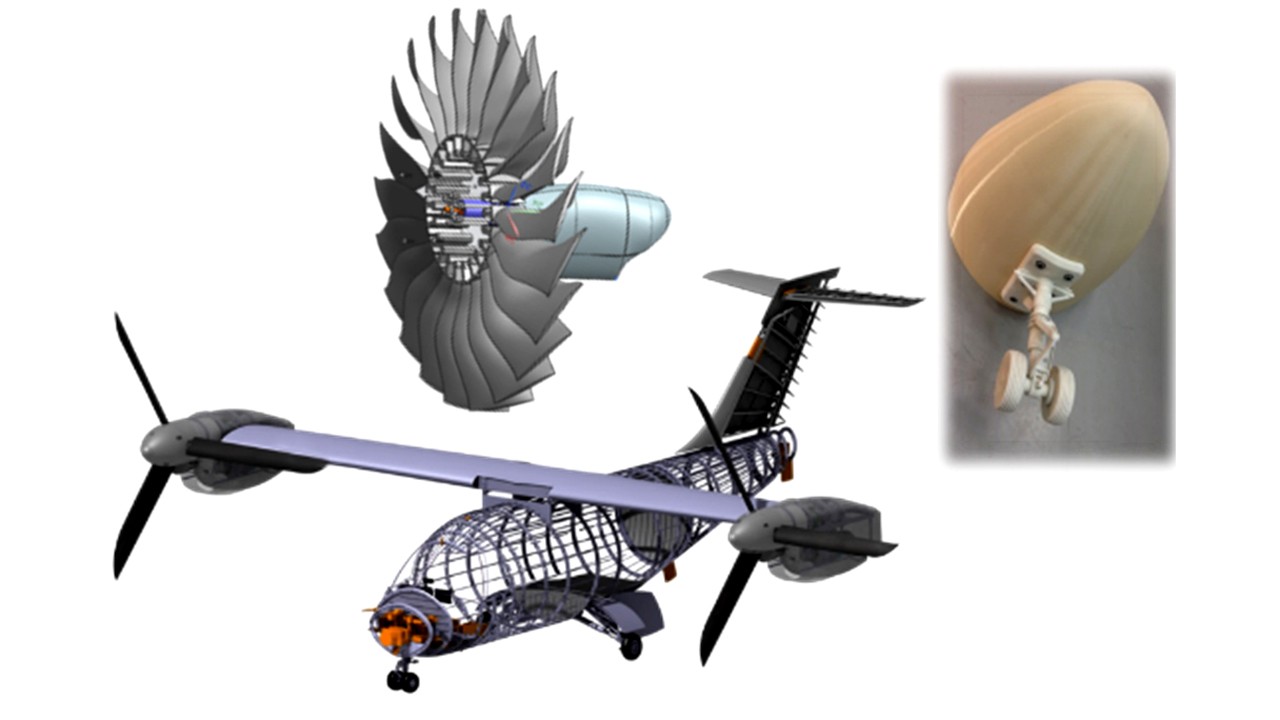

Design for Additve Manufacturing

We optimise products by reducing weight, applying topology optimisation (using biomimicry), and incorporating lattice structures when needed – all while considering the 3D printing/Additive Manufacturing process. Commonly used in aerospace, medical, robotics, and automation components, this approach can improve the functionality of redesigned products and reduce the number of assembly parts.

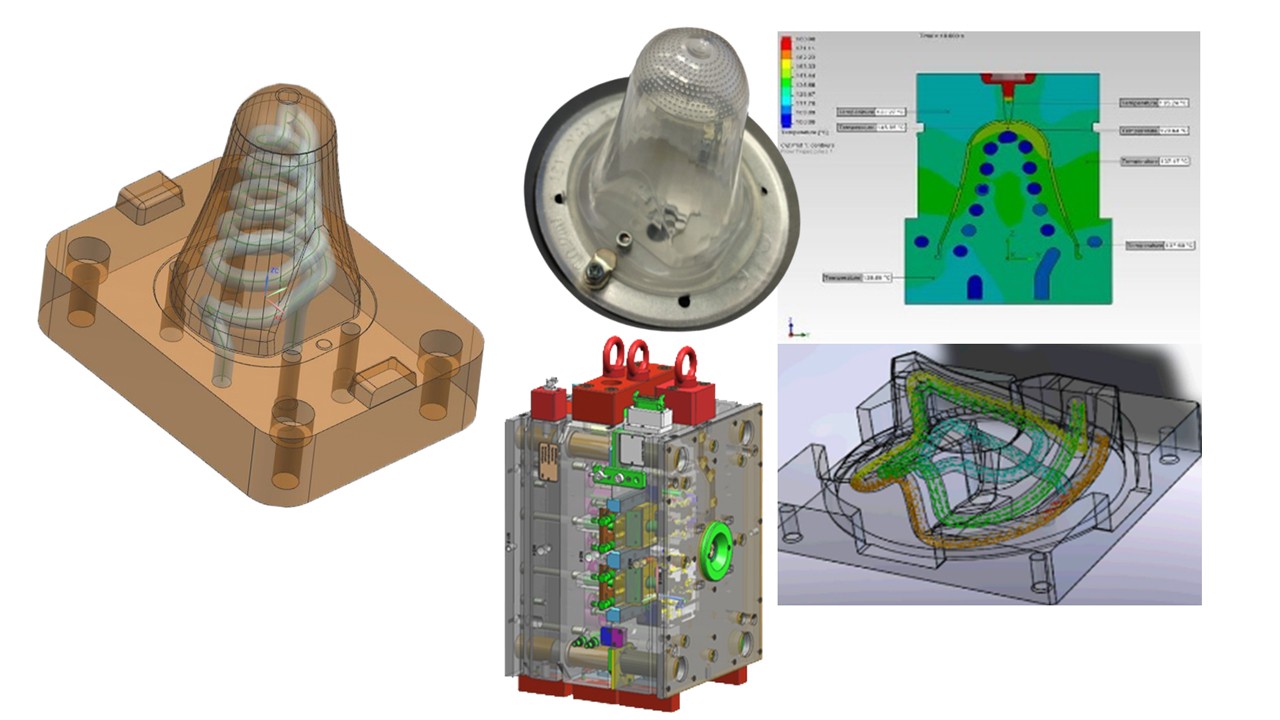

Rapid Tooling, Hybrid Tooling & Conformal Cooling

We have developed and fabricated several rapid tooling inserts for our industrial customers. Rapid tooling inserts are built using the Direct Metal Laser Melting process. Complex conformal cooling channels can be incorporated in the insert to improve product quality and shorten moulding cycle time.

Rapid Fixturing

Fast and flexible fabrication of jigs & fixtures could be done using additive manufacturing techniques. Complex fixtures could be designed and fabricated in non-traditional way.

Copper Printing

Copper 3D-printing with powder bed fusion technology enables precise, high-density copper printing with enhanced thermal and electrical properties.

Dry Electropolishing

Precisely smoothening, polishing, and deburring metal parts, Dry Electropolishing offers high-quality results faster and more efficiently than traditional methods. It provides superior surface finishes, including mirror-like finishes and defect-free surfaces, that outperform traditional polishing.

Unleash the Potential of Additive Manufacturing

Our Additive Manufacturing (AM) capabilities encompass a wide range of technologies, including:

- Rapid Prototyping: Quickly iterate and validate designs with functional prototypes.

- Functional AM: Produce end-use parts with the required mechanical properties.

- Multi-material AM: Combine materials within a single print for parts with varying stiffness, flexibility, or colour.

- Assembly Printing: Eliminate the need for separate components by printing functional assemblies.

For vibrant product development and production, our multi-colour multi-material technology allows you to create plastic parts with:

- Multiple Colours: Enhance aesthetics and branding with a wider colour palette.

- Varied Material Properties: Combine rigid and flexible regions within a single print for features like non-slip grips or living hinges.

- Simplified Assemblies: Reduce complexity by printing multi-functional parts, eliminating the need for separate components.

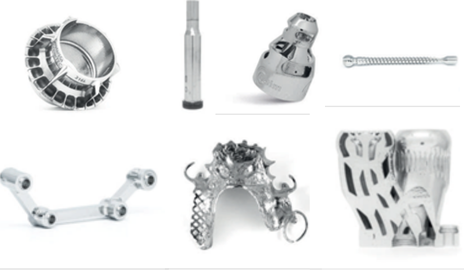

With Metal 3D Printing, we can unlock new frontiers in manufacturing together. By building complex objects layer-by-layer, this technology enables:

- Cost-Effective Production: Create intricate geometries that are difficult or expensive with traditional methods.

- Design Innovation: Unleash your design creativity with complex features and lattice structures.

Our Facilities

Our facilities include a spread of Additive Manufacturing Processes using various technologies such as Polymer Powder Bed Fusion, HP Multijet Fusion, Material Jetting, Vat Polymerization, Material Extrusion including Continuous Fiber Fabrication, Metal Laser Sintering, Selective Laser Melting, Metal Laser Cusing, etc., supported by post processing equipment such as Dry Electro Polishing, Micro Peening, Heat Treatment, CNC Mill/Turn, Laser Scanning, CMM, CT and Material Testing.

Type of AM machines & Material at AMIC

- Vat Photopolymerization: SLA Prox800

- Material Jetting: Objet 500 Connex3

- Powder Bed Fusion: HP5200, M290 (2 machines), Concept Laser M2, SLM280

- Material Extrusion (FDM): Fortus900, Fortus 450, F170, V-Shaper, Markforged FX 10

- Plastic/Polymer Material: PA, Nylon, PC, ABS, PC-ABS, Ultem, digital materials, Carbon Fiber

- Metal Material: S.S, Maraging Steel, Cobalt Chrome, Ti, Al, Inconel, Copper

-

Process:

Scanning of UV laser beam over the cross section of the model in liquid resin and building up layer by layer.Material Used:

Accura 60(PC Similar)Maximum Build size :

650mm x 750mm x 550mmApplication :

- Concept modeling

- Form fit, assembly tests

- Master pattern for vacuum casting

- Models for stress optical checking

- Other applications

-

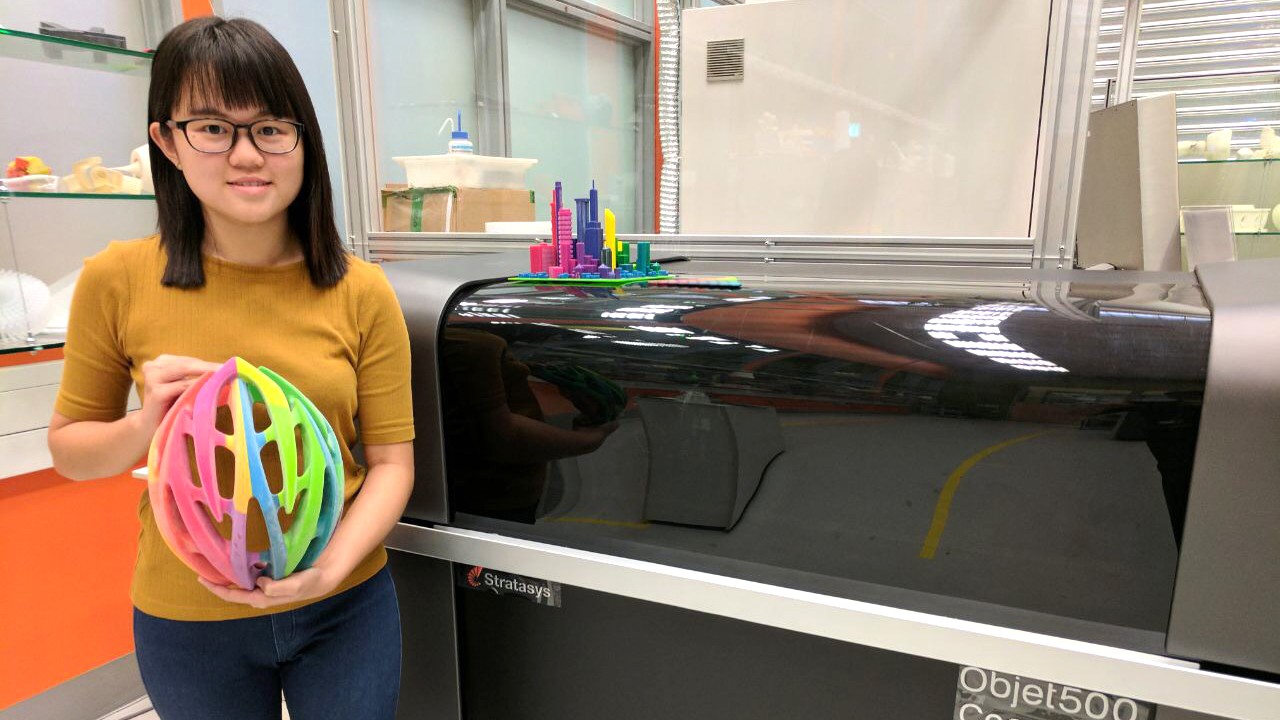

Process:

Inkjet print heads are used to deposit materials on demand onto a build platform. The material solidifies which allows to build layers on top of each other.

Material Used:

Clear, rubberlike photopolymers, and tough high-performance thermoplastics. Able to combine many colors and material properties into one model.

Maximum Build size :

490mm x 390mm x 200mm

Application :- Concept modeling

- Form fit, assembly tests

- Functional Prototypes

- Transparent and rubber like model

- Other applications

-

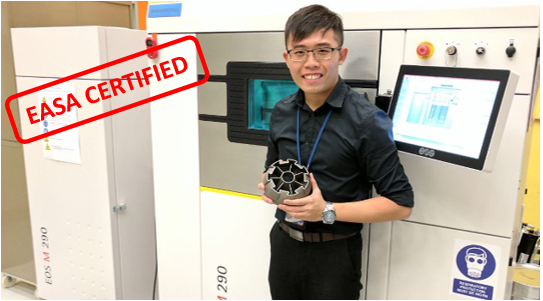

European Union Aviation Safety Agency (EASA) Certified

Process

Scanning of laser beam over the cross section of the model in the metal powder and building up layer by layer.Material used:

Stainless Steel, Maraging Steel (MS1), Aluminium (AlSi10Mg), Titanium (Ti64), Inconel 718, CopperMaximum Build Size:

250mm x 250mm x 325mmApplication:

- Rapid Tooling Insert with Conformal Cooling

- Metal components

- Hybrid prototypes

- Other applications

-

Process

Scanning of laser beam over the cross section of the model in the metal powder and building up layer by layer.Material used:

Stainless Steel, Maraging Steel (MS1), Aluminium (AlSi10Mg), Titanium (Ti64)Maximum Build Size:

250mm x 250mm x 280mmApplication:

- Rapid Tooling Insert with Conformal Cooling

- Metal components

- Hybrid prototypes

- Other applications

-

Process

Scanning of laser beam over the cross section of the model in the metal powder and building up layer by layer.Material used:

Stainless Steel 316L, Maraging Steel (MS1), Aluminium (AlSi10Mg), Titanium (Ti64)Maximum Build Size:

280mm x 280mm x 365mmApplication:

- Metal components

- Hybrid prototypes

- Aerospace, automotive and marine

- Other applications

-

Process:

The extrusion head heats the filament and ‘draw’ section of the part on the build platform. Model is built upwards in layer.Material Used:

ABS, PC, PC-ABS, UltemMaximum Build Size:

900mm x 600mm x 900mmApplication:

- Conceptual model

- Fit, form and functional applications

- Investment casting

- Other applications

-

Process

The extrusion head heats the filament and ‘draw’ section of the part on the build platform. Model is built upwards in layer.Material Used:

ABS, PC, PC-ABS, UltemMaximum Build Size:

400mm x 350mm x 400mmApplication:

- Conceptual model

- Fit, form and functional applications

- Functional prototypes

- Other applications

-

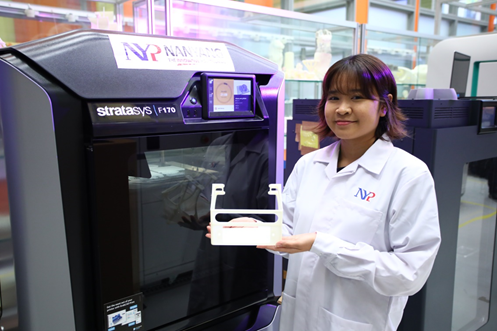

Process:

The extrusion head heats the filament and ‘draw’ section of the part on the build platform. Model is built upwards in layer.Material Used:

ABSMaximum Build Size:

254mm X 254mm X 254mmApplication:

- Conceptual model

- Fit, form and functional applications

- Functional prototypes

- Other applications

-

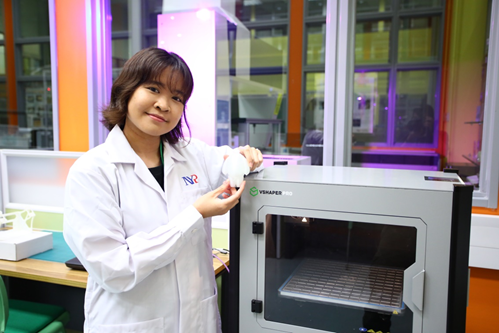

Process:

The extrusion head heats the filament and ‘draw’ section of the part on the build platform. Model is built upwards in layer.Material Used:

PEEK, PLA, ABSMaximum Build Size:

270mm x 270mm x 200mmApplication:

- Able to fabricate precision parts using PEEK which is highly resistant to heat and chemicals with detailed mechanical features

-

Process:

Powder-based technology utilising IR energy to fuse powder with light-absorbing ink and detailing agent.Material Used:

Polyamide (PA 12)Maximum Build Size:

380mm x 284mm x 380 mmApplication:

- Conceptual model

- Fit, form and functional applications

- Functional prototypes

- Other applications

-

Process

The Markforged FX10 uses a Continuous Filament Fabrication (CFF) process, which combines the deposition of layers of thermoplastic filament with reinforcement filaments such as carbon fiber. The printer's dual extrusion system allows it to print both the base material (such as Onyx) and the reinforcing material simultaneously.Material used:

OnyxTM, Onyx FRTM Onyx ESDTMMaximum Build Size:

375 mm x 300 mm x 300 mmApplication:

- Tooling & Manufacturing Fixtures

- End-Use Parts

- Functional Prototypes

- Aerospace Components

- Replacement Parts

-

Process:

The DLyte 100PRO is a cutting-edge compact surface finishing machine designed for industrial applications. It utilizes dry electropolishing technology to precisely smooth, polish, and deburr metal parts, offering high-quality results faster and more efficiently than traditional methods.

Material used:

Stainless Steel, Cobalt-Chrome, Titanium, Nickel-based alloys & Tool steel.

Maximum Part Size:

The maximum part size depends on the machine’s chamber size, which is 180 mm (Diameter) x 80 mm (Height). However, it is mainly used for polishing parts smaller than 100 mm (Diameter) x 50 mm (Height).

Applications:

- Automotive

- Semiconductor

- Medical & Dental components

- Aerospace components

- Precision Components

Your One-stop solution to industries

Connect with services such as Finite Element Analysis, Mould Flow Analysis, Reverse Engineering, and more.

Enrol in Additive Manufacturing / 3D printing short courses

Jointly conducted with the American Bureau of Shipping (ABS):

Jointly Conducted with Materialise:

- [NYP-CE1380] Deep Dive into 3D Printing (Classroom, Synchronous e-Learning)

- [NYP-CE1502] Digital Manufacturing: 3D Printing Applications (Classroom, Synchronous e-Learning)

- [NYP-CE1504] Anatomical Modelling and Engineering in Medical 3D Printing

Contact us

Mr Desmond Tan

Centre Director

- Tel: 6550 0674

- Email: desmond_tan@nyp.edu.sg

Mr Zaw Hlwan Moe

Master Specialist (Additive Manufacturing)

- Tel: 6550 0667

- Email: hlwan_moe_zaw@nyp.edu.sg